SuperNEMO demonstrator source foil production, a key step

On October 3 2017, after 4 years of Research & Development and production, the last SuperNEMO (Neutrino Ettore Majorana Observatory) demonstrator source foil was produced. This is an essential step for the scientific and technical program of the SuperNEMO international collaboration. Six IN2P3 laboratories are involved. The SuperNEMO demonstrator is a 4th generation detector for the study of neutrinoless double beta decay installed in the underground laboratory in Modane (LSM).

Situated in the underground laboratory in Modane in the Frejus tunnel protected from cosmic rays under 1700 m of rock (4200 m.water equivalent), the SuperNEMO demonstrator will study fundamental properties of neutrinos using events from source foils at the heart of the detector. SuperNEMO is a technique combining calorimetry and a tracker with a double beta (simultaneous emission of two electrons) source in the center. This technique considerably reduces background and allows discriminating between different processes.

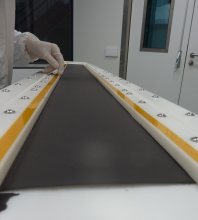

The source foils in the center contain about 7 kg of a Selenium isotope, 82Se. They are essentially composed of this isotope with 10 % PVA glue (Polyvinyl alcohol) of average thickness 300 microns, in a thin Mylar plastic envelope 12 microns thick for mechanical strength. The foils are 2.7 m long and 13.5 cm wide. They will be installed side by side in a frame (designed by a laboratory in Texas), similar to a vertical blind, except they will be attached in a fixed manner on the top and on the bottom.

Of the 34 82Se foils that will be installed, 23 were produced at LAPP (Laboratoire d’Annecy de Physique des Particules), almost 70 % and 11 were produced by ITEP (Institute for Theoretical and Experimental Physics in Moscow, Russia).

Of these 34 foils, 18 were produced with the method already used in previous NEMO detector generations in which the part containing the 82Se is in one piece surrounded by microperforated Mylar allowing for easy drying of the 82Se-PVA mixture. This production was done in close collaboration between LAPP, LSM and ITEP with numerous exchanges within the frame of the France-Russia IN2P3/ITEP agreement.

16 foils were produced with an innovative method developed at LAPP needing several years of Research & Development. It consists in preparing 82Se-PVA standalone pads that are then bagged inside raw Maylar (not perforated) thus less prone to contamination. Indeed, the major difficulty during source production is to ensure that once produced their radioactivity stays at least 50 million times below natural radioactivity (100 disintegrations per second for one kilogram of bananas compared to 1 disintegration every 6 days from the source foils). This requires working with material and tools that are carefully selected for their very good radiopurity and protecting against dust containing natural radioactivity.

Thus, the production chain is installed in a clean room with laminar flux of ISO class 5 or 6. Selenium has been purified using different methods in laboratories from Russia (Dubna, ITEP) or in the USA. Each item entering the demonstrator has to be validated by radiopurity measurements in germanium detectors at LSM or CENBG (Centre d’Etudes Nucléaire de Bordeaux Gradignan) or in an even more sensitive tool, the BiPo detector designed specifically for these measurements by LAL (Laboratoire de l’Accélarateur Linéaire d’Orsay) and installed in the underground laboratory in Canfranc (LSC) in Spain.

The end of the foil production was announced during the recent collaboration meeting held beginning November at LAL, followed by the official SuperNEMO inauguration November 9 2017 in Modane. The schedule foresees a source foil installation in spring 2018, followed by the closing of the demonstrator and subsequent data taking. The teams involved in SuperNEMO are impatiently awaiting this data.

Physics contact : Dominique Duchesneau, head of SuperNEMO at LAPP

Technical contact : Andrea Jeremie, SuperNEMO technical coordinator

Thumbnail picture : SuperNEMO Selenium foil during production in a clean room