The challenges of the ITk pixel detector

CERN’s Large Hadron Collider (HL-LHC) project aims to push the LHC’s performance to its maximum, to increase the potential for the discovery of new physics and to measure the properties of the Higgs boson with unprecedented precision, in order to search for even small deviations between theory and experimental measurements. The aim of the HL-LHC is to increase the instantaneous luminosity of the LHC to multiply the amount of data accumulated by the experiments, in particular the ATLAS experiment.

This increase in instantaneous luminosity will have two important consequences for the ATLAS detector. The first concerns the readout electronics, which will have to undergo a major overhaul in order to be able to process the data stream more quickly and also to enable the signals of interest to be sorted more efficiently. This is the case for the reading electronics of the electromagnetic calorimeter, in which LAPP is now actively involved.

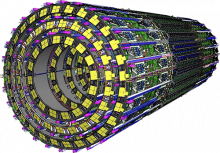

The increase in luminosity at the HL-LHC will also lead to a massive increase in particle density and radiation levels, to the extent that parts of the current detectors will have to be completely replaced. This is the case for the ATLAS inner track detector, which is designed to detect the passage of charged particles as close to the collision point as possible. This new detector, called ITk, will cover seven times more surface area than the current detector, for a total number of electronics channels that is two orders of magnitude greater. LAPP has been involved since the start of the project in the design and construction of the innermost part, the pixel detector.

An innovative design

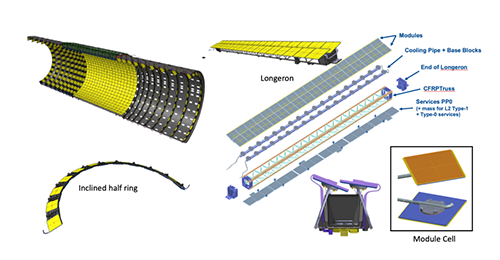

Its innovative geometry, tilted at the front to minimise the active area and thus the cost, and to maximise physics performance, was proposed by LAPP physicist Teodore Todorov in 2012 [1]. The ITk pixel detector will consist of 5 layers, which will be equipped with more than 10,000 silicon modules. The pixel modules, with a size of 4×4 cm2, will have a granularity eight times finer than that of the current detector, and will make it possible to reconstruct the tracks of charged particles as close as possible to the point of interaction with a very high degree of accuracy, even in events with up to 140 simultaneous collisions.

One of the most critical points in the design of this pixel detector is the routing of the power supply, control commands and data readout. Each of the 10,000 pixel modules will consume up to 6 watts of power, their silicon detector part will be subjected to a high depletion voltage of up to 600 V, and each of their 4 readout chips will have to transmit 1.25 Gb of data per second. In addition to these high technical specifications, it is also necessary to minimise the load loss to a few milliohms over the entire power supply chain in order to limit the heating of the detector, to transmit the signal with almost no attenuation over a length of 6 metres, to reduce the footprint to a minimum in order to be able to integrate all the cables of the 10,000 modules in an over-stressed space (maximum tolerance of a hundred microns in certain areas of the detector! ), use of materials resistant to radiation up to 1 GigaRad, use of ultra-compact and mechanically secured connectors to avoid any untimely disconnection, and all of this must obviously be achieved by minimising the quantity of material, in particular copper, so as not to degrade the resolution of the detector and the physics performance!

Several years of work for the LAPP teams

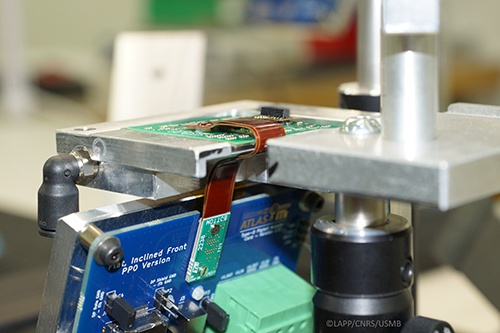

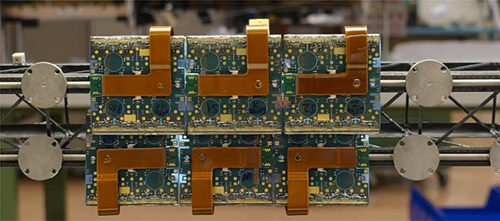

The ITk team at LAPP has been working on this technical challenge since 2014. In 8 years, three prototyping campaigns have been completed and qualified at LAPP. The initial idea was to develop long flexible circuits, using 5 micron thick copper tracks, and covering the full length of the ladders over 1.20m. A second series of shorter and thicker prototype flexes was produced in 2018, following a major change in the geometry of the detector to mechanically separate the central part (barrel) from the front part (inclined rings) and a major change in the specification of the transmission chain. Finally, the latest version, dating from 2021, is much more modular: the new prototypes are made up of independent flexible ’pigtails’ that connect each silicon module to a rigid ’PP0’ board that distributes power and commands and routes data to dedicated cables. This latest design of electrical services simplifies the replacement of any faulty modules during the various stages of detector assembly and testing, from the production sites to CERN.

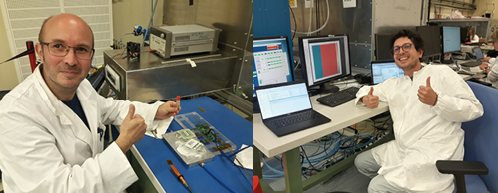

The prototype pigtails and PP0 were fully electrically qualified in 2022, and also passed radiation testing. In addition to the technical challenges related to the electronics, the LAPP ITk team carried out numerous mechanical developments, aiming to develop tools for hot-folding the circuits to fit precisely into the allocated mechanical envelopes, as well as a set of specific supports for testing the folded pigtails in 3 dimensions, and tools dedicated to inserting and securing the connectors on the fragile pixel modules. This integration stage was also a great success, since in autumn 2022, 18 modules were assembled at CERN by the LAPP team and integrated into a fully functional full-scale model of the detector.

All of this development work has enabled the project to pass the Final Design Review on 30 November 2022. This important victory marks the official start of the pre-production phase of 10% of the components for 2023. During this pre-production phase, the aim will be to qualify the manufacturers’ large-scale production capacity and to develop optimal automation of the quality control that will be carried out at each stage of production. This pre-production stage is crucial for the LAPP, which will have to supply 5,000 pigtails and 500 PP0 cards precisely folded and fully tested to the ITk collaboration by 2025.